When I think of making an environmentally sound decision, especially if it pertains to green elevators or a lift purchase, I can point out 3 contributing factors.

#1 Where is the device manufactured?

This seems pretty obvious but if you can purchase a locally manufactured elevator or lift, the transportation impact can be minimized. Buying local not only reduces emissions it saves you money on shipping costs associated with replacement parts.

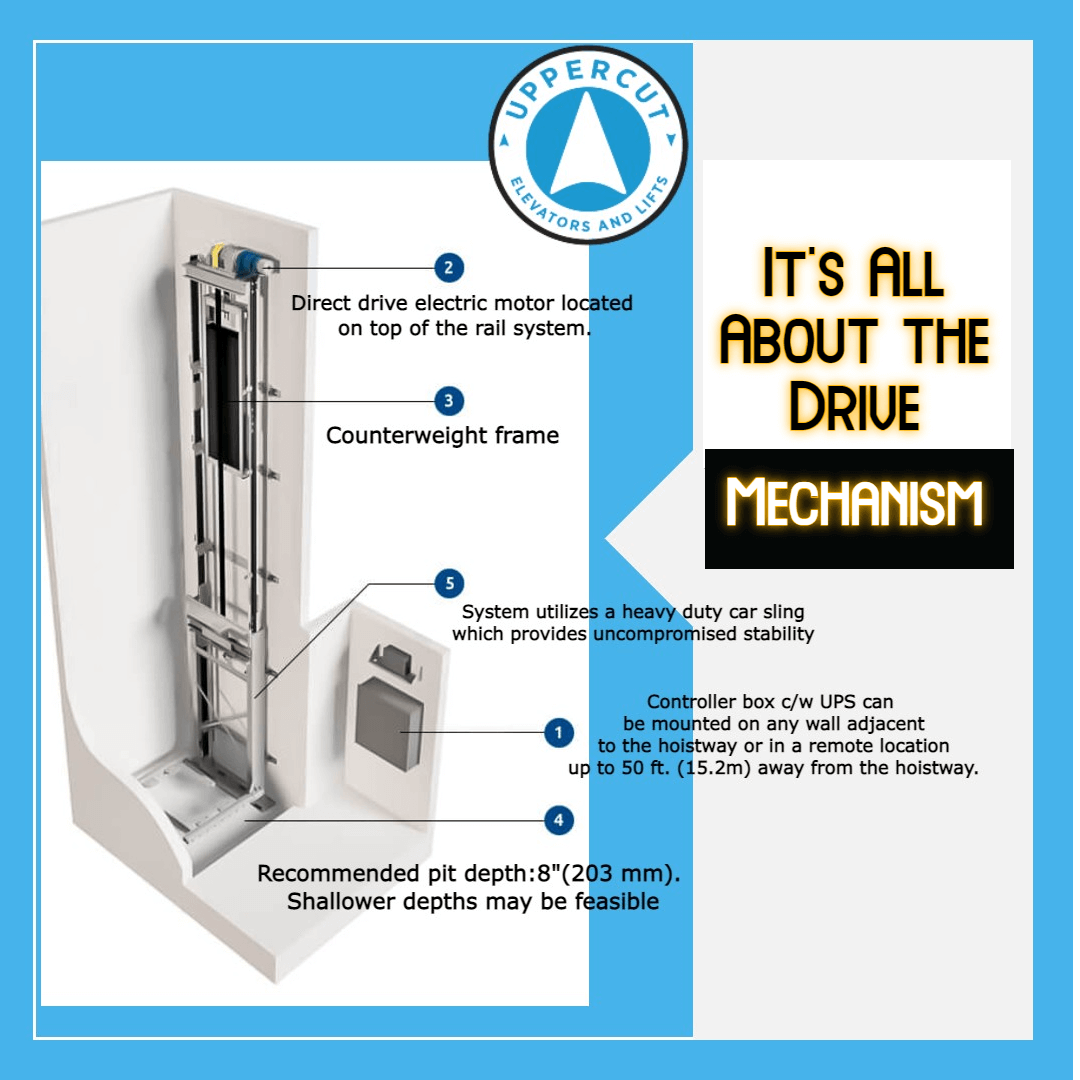

#2 What impact could the drive mechanism have on the environment?

Devices that utilize large hydraulic pumps and reservoirs may need to have precautionary measures were taken, such as oil separators in the event of a hydraulic oil leak. This is to ensure that the oil cannot seep into the ground or water table. Some jurisdictions in the past have asked that food grade oil is used in order to alleviate this concern. Elevators and lifts that utilize a inline-Counter Weight don’t actually pose this risk, as no hydraulic fluid is used. These greener solutions only require a 6″- 12″ pit so there is less concern with disturbing ground water.

#3 What are the ongoing energy costs?

This cost is two fold; the energy consumed as it relates to the environment and the monetary cost directly to you. Do your research on how much energy your elevator or lift will require operating. Devices with a mechanical advantage such as a inline counterweight drive will be up to 50% more energy efficient that a comparative hydraulic unit. Hydraulic elevators have to pump fluid into a cylinder which is often located in a separate machine room.

It doesn’t matter if your goal is to consciously protect the environment or simply save some money (energy costs, site preparation , and maintenance), it’s apparent that the two can go hand in hand.

For more information on Elevators and Lifts please click here or contact us for a free consultation.